Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- Manufacturing process of fire clay insula

- Aggregates Used For the Production of Ins

- Pros and cons of lightweight mullite bric

- the development of the refractory brick i

- The Use of Mullite Insulation Bricks

- Pollution and treatment in the production

- Classification of mullite insulation bric

- Thermal Shock Resistant Fireproof Heat In

- Production Process Methods of Refractory

- Refractory material production process

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

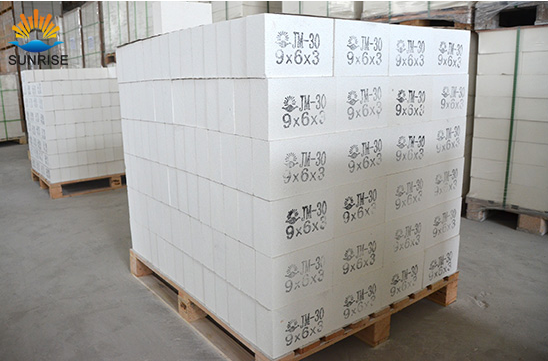

Classification and use of mullite insulation brick

Date:2017-04-28 14:59 | From:Zhengzhou Sunrise Refractory | Author:admin

The classification and use of mullite insulation brick:

It is divided into light and heavy mullite brick according to the density, according to the use of different temperature is divided into: 1350 mullite brick, 1450 mullite brick, 1550 mullite brick and so

on.

Properties and application of mullite Insulation brick:

Refractoriness is higher, can reach up to 1790 ℃ or more. Load softening starting temperature is 1600 ~ 1700 ℃. Room temperature compressive strength is 70 ~ 260MPa. The thermal shock

resistance is good. There are sintered mullite brick and fused mullite brick. Sintered mullite brick is high bauxite clinker as the main raw material, adding a small amount of clay or bauxite as a

binder, made by molding, sintering.

Fused mullite brick is bauxite, industrial alumina and refractory clay as raw materials, adding charcoal or coke fine particles as a reducing agent, after forming, use reduction fused method to

manufacture. The crystallization of the fused mullite is greater than that of the sintered mullite, and the thermal shock resistance is better than that of the sintered product. Their high temperature

performance mainly depends on the alumina content and the homogeneity of the mullite phase with the glass distribution.

manufacture. The crystallization of the fused mullite is greater than that of the sintered mullite, and the thermal shock resistance is better than that of the sintered product. Their high temperature

performance mainly depends on the alumina content and the homogeneity of the mullite phase with the glass distribution.

Mainly used for hot stove roof, blast furnace and the bottom of the furnace, glass furnace regenerator, ceramic sintering kiln, oil cracking system dead angle lining.