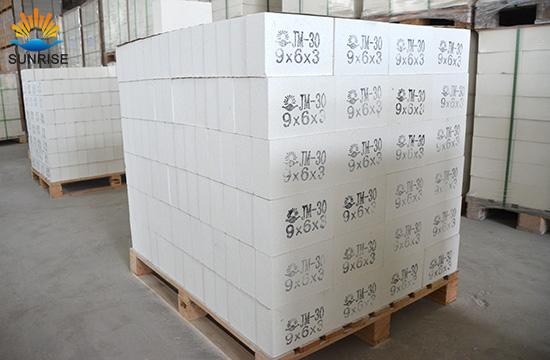

mullite insulation brick

- Classification Temperature:1260 (℃)

- Bulk Density :0.55-0.60 (g/cm3)

- Cold Crushing Strength:1.2 (Mpa)

- Modulus of Rupture:0.9 (Mpa)

- Reheating Linear Change (%) CT-30 ℃X 8H :1230℃ -0.5

E-mail:sales@sunriserefr.com

We're here to help: Easy ways to get the answers you need.

Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- Aggregates Used For the Production of Ins

- The Use of Mullite Insulation Bricks

- the development of the refractory brick i

- Classification of mullite insulation bric

- Refractory material production process

- Manufacturing process of fire clay insula

- Thermal Shock Resistant Fireproof Heat In

- Pros and cons of lightweight mullite bric

- Pollution and treatment in the production

- Production Process Methods of Refractory

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

Feature:

Description

Mullite insulation brick are high alumina refractories mainly made from good quality and pure raw materials.In generally, alumina accounts 65%-75%. Besides mullite,there are also glass phase and christobalite as well as corundum which are good grade fillings. Mullite insulation brick are widely used for lining in high temperature kilns such as shuttle kiln,roller kiln,glass kiln and petroleum kilns.

Specifications

1.Low thermal conductivity, good heat insulation.

2.Low thermal melting point. Lightweight mullite insulating bricks save heat and energy.

3.Low impurity content,high temperature resistance; higher alumina content ensures good performance.

4.Customized shapes to reduce bricks quantity and cost.

5.Dense,compact and accurate structure,low porosity rate.

6.High loading temperature,corrosion resistance.

Application

Due to its lightweight and good insulating performance,our mullite insulation brick has broad use for fire resistance lining in heat side and insulating layers, thus increases energy efficiency greatly. Mullite lightweight bricks are popular in hot blast kiln crown,flame side and bottom parts; glass melting furnace regenerator,ceramic sintering kiln,Petroleum cracking system corners and linings,ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc.

Mullite insulation brick are high alumina refractories mainly made from good quality and pure raw materials.In generally, alumina accounts 65%-75%. Besides mullite,there are also glass phase and christobalite as well as corundum which are good grade fillings. Mullite insulation brick are widely used for lining in high temperature kilns such as shuttle kiln,roller kiln,glass kiln and petroleum kilns.

Specifications

1.Low thermal conductivity, good heat insulation.

2.Low thermal melting point. Lightweight mullite insulating bricks save heat and energy.

3.Low impurity content,high temperature resistance; higher alumina content ensures good performance.

4.Customized shapes to reduce bricks quantity and cost.

5.Dense,compact and accurate structure,low porosity rate.

6.High loading temperature,corrosion resistance.

Application

Due to its lightweight and good insulating performance,our mullite insulation brick has broad use for fire resistance lining in heat side and insulating layers, thus increases energy efficiency greatly. Mullite lightweight bricks are popular in hot blast kiln crown,flame side and bottom parts; glass melting furnace regenerator,ceramic sintering kiln,Petroleum cracking system corners and linings,ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc.

Technical Data:

| Sunrise Brand | JM23 | JM26 | JM28 | JM30 | JM32 | |

| USA Brand | IFB2300 | IFB2600 | IFB2800 | IFB3000 | IFB3200 | |

| Classification Temperature (℃) | 1260 | 1430 | 1540 | 1650 | 1760 | |

| Bulk Density (g/cm3) | 0.55-0.60 | 0.78 | 0.88 | 1.03 | 1.25 | |

| Cold Crushing Strength (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

| Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

| Reheating Linear Change (%) CT-30 ℃X 8H | 1230℃ -0.5 | 1400℃ -0.5 | 1510℃ -0.5 | 1620℃ -0.9 | 1730℃ -0.9 | |

| Thermal Expansion 1000℃(%) | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

| Thermal conductivity(W/m.k) | 400℃ | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

| 600℃ | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

| 800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

| 1000℃ | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

| Al2O3 (%) | 37 | 54 | 64 | 72 | 77 | |

| Fe2O3 (%) | 1.0 | 0.9 | 0.8 | 0.7 |

0.5 |

|

Inquiry:

If you have any needs our help or are interested in our products, you can click online advisorychat with us online, or call our customer service telephone: 0086-0371-63838939. We will sincerely serve for you!