Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- Manufacturing process of fire clay insula

- the development of the refractory brick i

- Pollution and treatment in the production

- Aggregates Used For the Production of Ins

- Pros and cons of lightweight mullite bric

- Refractory material production process

- Thermal Shock Resistant Fireproof Heat In

- Classification of mullite insulation bric

- The Use of Mullite Insulation Bricks

- Production Process Methods of Refractory

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

Advantages of Insulating Brick

Date:2016-02-25 12:00 | From:Zhengzhou Sunrise Refractory | Author:admin

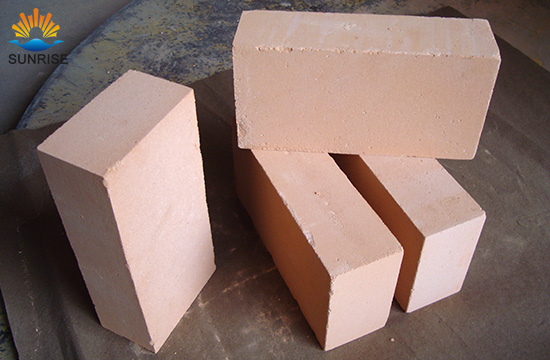

Compared to common refractory brick, insulating brick has light weight, uniform mircro pores and high porosity. So, it can reduce the heat loss of furnace walls and fuel cost. Insulating brick has low heat storage, so it can be heated and cooled quickly and allows acceleration of cyclical operations. Insulating brick can be used within 900-1650℃.

Insulating brick has low thermal conductivity, low heat capacity, low impurity content, high strength, good resistance to thermal shock and corrosion by acid and basic atmosphere and high accuracy.

Insulating brick has the following advantages:

1) Economy

It can reduce the cost of the foundation and cross-section of the frame and save reinforced concrete. As a result, it can reduce the total cost of masonry by over 5% compared to fire clay bricks.

2) Applicability

Insulting brick can increase the usable area of silica insulating brick. Due to the insulation of aerated concrete, it has great insulating performance.

3) Construction

Insulating brick can be easily processed and constructed. Due to light weight, it can reduce the labor intensity, improve construction efficiency, and shorten the construction period.

Insulating brick is widely used in the hot face lining of industrial furnaces (annealing furnace, carbonization furnace, tempering furnace refining furnace, cracking furnace, roller kiln, and tunnel kiln, etc.), insulating back lining of various furnaces and reducing atmosphere furnace.