Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- Aggregates Used For the Production of Ins

- Pollution and treatment in the production

- Classification of mullite insulation bric

- Pros and cons of lightweight mullite bric

- the development of the refractory brick i

- Manufacturing process of fire clay insula

- Thermal Shock Resistant Fireproof Heat In

- Production Process Methods of Refractory

- Refractory material production process

- The Use of Mullite Insulation Bricks

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

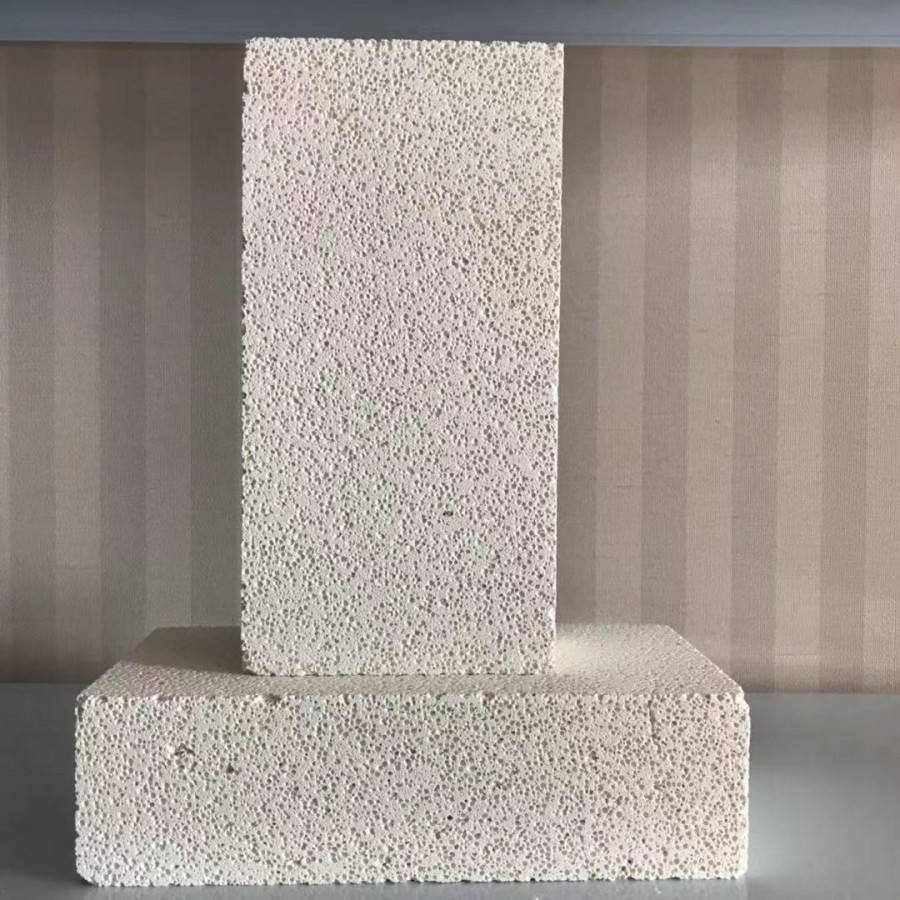

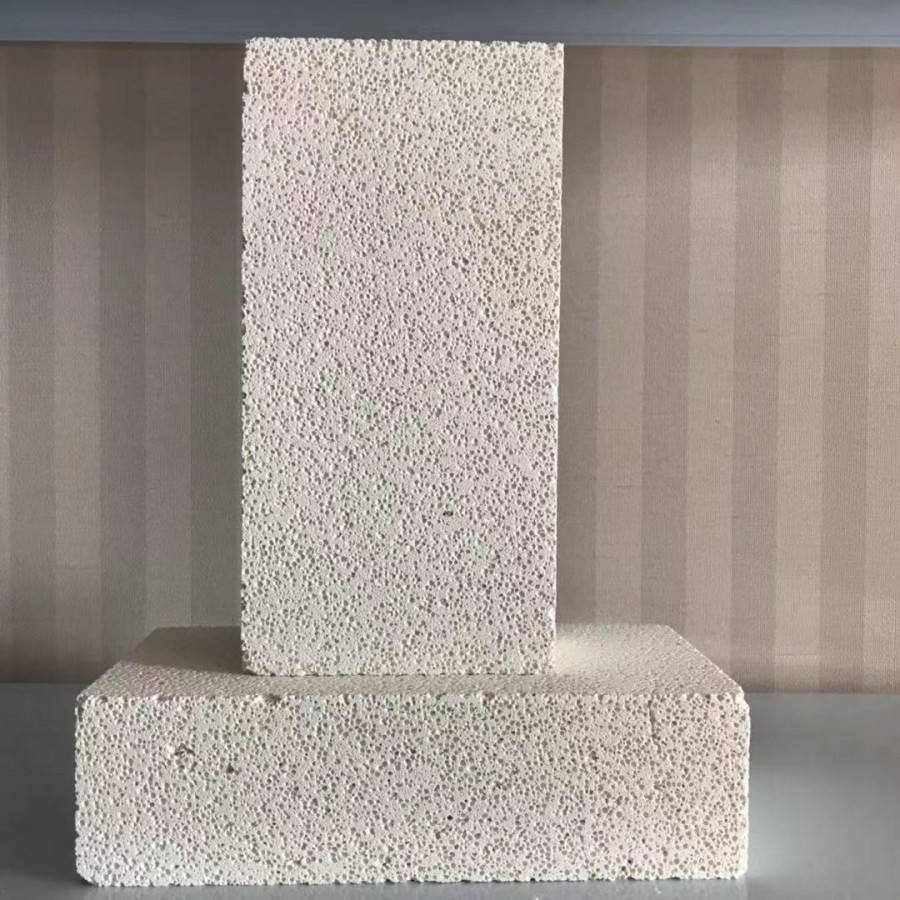

Characteristics and application of mullite brick

Date:2020-02-20 15:33 | From:Zhengzhou Sunrise Refractory | Author:admin

Mullite refractory bricks and corundum mullite bricks have the advantages of high load softening temperature, low high-temperature creep rate, and good thermal shock resistance. They are widely used in blast furnace hot blast furnaces, glass melting furnaces, dry quenching and heating furnaces and other industries. On the kiln.

Mullite refractory bricks are easily eroded by alkaline refractory bricks at high temperatures. In addition, at high temperatures, mullite can react with water vapor to form Al2O3 and be damaged. Therefore, mullite refractory bricks are not suitable for long-term use in environments with high alkaline slag and high water vapor content.

In addition to mullite and its composite refractory bricks with corundum, mullite can also be used with other materials to improve its performance, such as zircon mullite refractory bricks, mullite-silicon carbide refractory bricks, etc. The so-called zircon mullite refractory brick is a mullite-zirconia composite material. However, because zirconia is expensive, in actual production, zircon mullite clinker or refractory brick is often obtained by reacting Al2O3 or alumina with zircon.

The manufacturing methods of such refractory bricks and raw materials include electric melting method and sintering method. Aluminum-zirconium-silicon (AZS) refractory bricks made by electrofusion have been discussed in fused zirconium corundum bricks. Zircon mullite clinker is prepared by calcining Al2O3 and ZrSiO4 ingredients, and then crushing, kneading, molding and firing to obtain zircon mullite refractory bricks, that is, sintered AZS bricks.

If you are interested in our fused azs bricks, or need other types of refractory materials, please contact our Tianyang Refractory Group, we will definitely provide you with the best quality refractory materials and the most reasonable quotation.

Mullite refractory bricks are easily eroded by alkaline refractory bricks at high temperatures. In addition, at high temperatures, mullite can react with water vapor to form Al2O3 and be damaged. Therefore, mullite refractory bricks are not suitable for long-term use in environments with high alkaline slag and high water vapor content.

In addition to mullite and its composite refractory bricks with corundum, mullite can also be used with other materials to improve its performance, such as zircon mullite refractory bricks, mullite-silicon carbide refractory bricks, etc. The so-called zircon mullite refractory brick is a mullite-zirconia composite material. However, because zirconia is expensive, in actual production, zircon mullite clinker or refractory brick is often obtained by reacting Al2O3 or alumina with zircon.

The manufacturing methods of such refractory bricks and raw materials include electric melting method and sintering method. Aluminum-zirconium-silicon (AZS) refractory bricks made by electrofusion have been discussed in fused zirconium corundum bricks. Zircon mullite clinker is prepared by calcining Al2O3 and ZrSiO4 ingredients, and then crushing, kneading, molding and firing to obtain zircon mullite refractory bricks, that is, sintered AZS bricks.

If you are interested in our fused azs bricks, or need other types of refractory materials, please contact our Tianyang Refractory Group, we will definitely provide you with the best quality refractory materials and the most reasonable quotation.