Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- Manufacturing process of fire clay insula

- the development of the refractory brick i

- Production Process Methods of Refractory

- Pros and cons of lightweight mullite bric

- Aggregates Used For the Production of Ins

- Pollution and treatment in the production

- Thermal Shock Resistant Fireproof Heat In

- Classification of mullite insulation bric

- The Use of Mullite Insulation Bricks

- Refractory material production process

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

Can high temperature lining be used only for insulating bricks or refractory bricks?

Date:2019-08-13 16:58 | From:Zhengzhou Sunrise Refractory | Author:admin

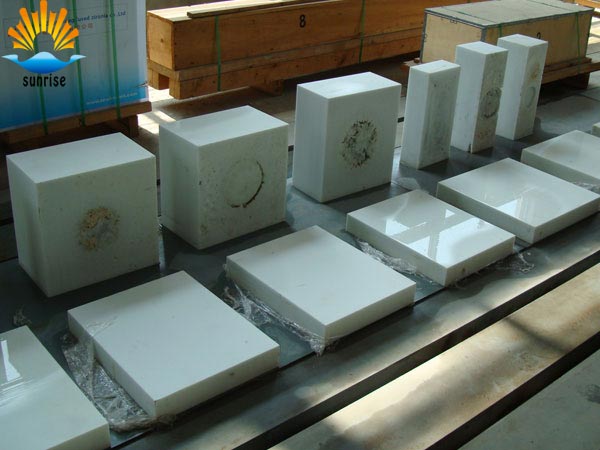

Most of the high-temperature linings are composed of multi-layer refractory materials. The working layer is made of refractory bricks, the insulation layer is made of heat-insulating bricks, and the insulation layer is made of heat-insulating bricks. If only heat-insulating bricks or refractory bricks are used, it will be not durable or the heat will be seriously lost. It is not in line with energy conservation and environmental protection requirements.

Is it possible to use only insulating bricks or only refractory bricks for high-temperature linings? Insulating bricks and refractory bricks are commonly used refractory materials and thermal insulation materials in kiln and various high temperature equipment. Although they are brick refractory materials, their performance and use are completely different.

The main function of the thermal insulation brick is to keep warm and reduce the loss of heat. The thermal insulation brick generally does not directly contact the flame, and the refractory brick generally contacts the flame directly. Refractory bricks are mainly used to withstand the flame roasting. Generally divided into two types, namely, amorphous refractory materials and shaped refractories.

Insulation performance: The thermal conductivity of insulating bricks is generally 0.2-0.4 (average temperature 350 & plusmn; 25 ° C) w / mk, while the thermal conductivity of refractory bricks is 1.0 (average temperature 350 & plusmn; 25 ° C) w / mk or more, which is available The insulation performance of the insulation bricks is much better than that of the refractory bricks.

The high temperature lining is made of a variety of refractory materials. If the high temperature lining is only made of insulating bricks or only refractory bricks? Of course, the current high-temperature equipment is guided by saving emissions, and the better the thermal insulation effect, the more economical, the greater the cost of fuel can be reduced in one year.

Lightweight insulation bricks are fired after adding some special substances to the manufacture of refractory bricks. Its porosity is twice as high as that of ordinary refractory bricks, and the density of refractory bricks is 0.5 times smaller than that of homogeneous refractory bricks; 7 times. The thermal conductivity is small, so it can be used as a heat insulation layer or lining of the furnace to reduce heat loss; for intermittent operation of the furnace, the furnace wall heat storage and heat loss can be reduced by 80%.

The refractory bricks of the light insulation bricks and the general materials of the same material have little difference, and the load softening point is slightly lower. If the lightweight bricks are used at high temperatures for a long time, they will continue to sinter and shrink, causing cracks and even damage. Therefore, most lightweight bricks have the highest temperature problem. For example, the highest density of lightweight clay bricks is only 1150 ° C, the temperature of lightweight high alumina bricks does not exceed 1350 ° C, and the temperature of lightweight mullite bricks does not exceed 1500 ° C. The quality silicon brick can reach 1600 °C. Because the lightweight silica brick does not have the problem of high temperature shrinkage, the volume is relatively stable, so it can be used to build a lining that directly contacts the furnace gas.

If you want to get more information about refractory bricks for sales, please contact Sunrise Refractory Company, we will serve you sincerely.