Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- The Use of Mullite Insulation Bricks

- Pros and cons of lightweight mullite bric

- the development of the refractory brick i

- Production Process Methods of Refractory

- Pollution and treatment in the production

- Aggregates Used For the Production of Ins

- Classification of mullite insulation bric

- Refractory material production process

- Thermal Shock Resistant Fireproof Heat In

- Manufacturing process of fire clay insula

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

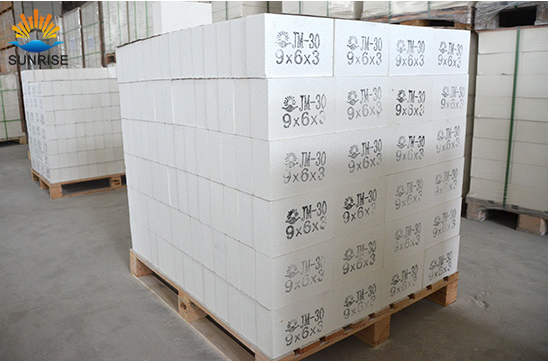

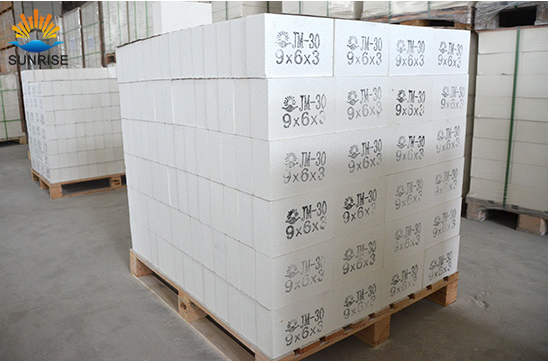

The product properties of Mullite Insulation Brick

Date:2016-09-07 17:54 | From:Zhengzhou Sunrise Refractory | Author:admin

The refractoriness of mullite insulation brick is very high. The highest can resist high temperature of 1800 degrees Celsius, but when from 1600 to 1700 degrees Celsius, heat preservation brick

will begin to soften, will not burn. And then it also has a high degree of pressure, presumably in the 260 M/pa. Mullite brick is to adopt high quality high purity refractory powder, according to the

requirements of products, to add the organic composite fillers, by vacuum extrusion forming, through high temperature sintering synthetic complex lightweight mullite product.

1. Low thermal conductivity, have very good heat insulation effect.

2. Mullite insulating brick low melt, due to the low thermal conductivity, the accumulation of mullite series light insulating brick has little heat, energy saving effect is obvious in the intermittent

operation.

3. Low content of impurities, with very low content of iron boxes alkali metal oxide, therefore, refractoriness is high.Higher aluminum content makes it still keep good performance under the

reducing atmosphere.

4. The thermal stage crushing strength of mullite insulation brick is high.

5. Appearance size precision, speed up the building speed, reduce the refractory mortar usage amount, to ensure the masonry strength and stability, thus prolonging the life of the lining.

6. Mullite insulating brick can be processed into special shape. In order to reduce brickwork blocks and paving seam.

will begin to soften, will not burn. And then it also has a high degree of pressure, presumably in the 260 M/pa. Mullite brick is to adopt high quality high purity refractory powder, according to the

requirements of products, to add the organic composite fillers, by vacuum extrusion forming, through high temperature sintering synthetic complex lightweight mullite product.

1. Low thermal conductivity, have very good heat insulation effect.

2. Mullite insulating brick low melt, due to the low thermal conductivity, the accumulation of mullite series light insulating brick has little heat, energy saving effect is obvious in the intermittent

operation.

3. Low content of impurities, with very low content of iron boxes alkali metal oxide, therefore, refractoriness is high.Higher aluminum content makes it still keep good performance under the

reducing atmosphere.

4. The thermal stage crushing strength of mullite insulation brick is high.

5. Appearance size precision, speed up the building speed, reduce the refractory mortar usage amount, to ensure the masonry strength and stability, thus prolonging the life of the lining.

6. Mullite insulating brick can be processed into special shape. In order to reduce brickwork blocks and paving seam.