Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- the development of the refractory brick i

- Thermal Shock Resistant Fireproof Heat In

- The Use of Mullite Insulation Bricks

- Aggregates Used For the Production of Ins

- Classification of mullite insulation bric

- Manufacturing process of fire clay insula

- Production Process Methods of Refractory

- Pros and cons of lightweight mullite bric

- Pollution and treatment in the production

- Refractory material production process

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

Glass Refractory In China

Date:2016-08-12 17:59 | From:Zhengzhou Sunrise Refractory | Author:admin

China's glass industry is developing rapidly, and has become the world's first glass production power. The rapid development of the glass industry naturally promotes the development and

technological progress of China's glass furnace refractory materials. Compared with the traditional process, modern glass production technology has a qualitative leap which towards the

direction of higher efficiency, lower energy consumption and better product quality. Accordingly, the technical level of glass furnace which is as the core equipment of glass production is also in

constant progress, for instance, widely adopt new technologies to improve the combustion intensity, strengthen heat transfer effect, reduce heat loss and educe the pollution of products and

environment.

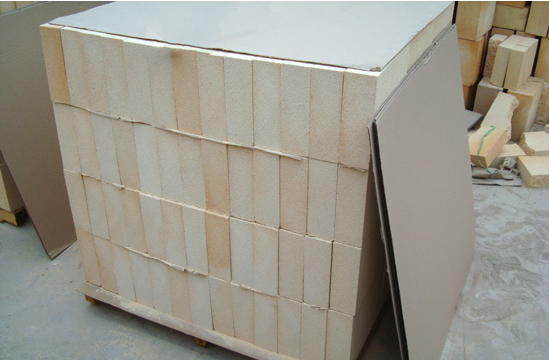

The technological progress of glass furnace requires a variety of high quality refractory bricks as the guarantee condition which can withstand high temperature, resist to strong chemical corrosion

and bear severe stress damage. In order to achieve the new furnace technology of high efficiency, energy saving and low pollution, it is very important to combine and use several kinds of high

quality refractory in one glass furnace, for example, fused cast AZS brick 33# is mainly used in relatively low temperature and corrosive parts of glass furnace such as working ends, feeder

channel.

Go through years of work and the efforts of all aspects, the glass refractory in China has made significant progress, greatly narrowed the gap with foreign, laid a more solid foundation for

enterprise development. As long as the next step to strengthen macro management, concentrating in taro in error problem to solve, we can make greater contributions to the development of glass

industry.

High quality refractory is not only the consumption materials to modern high temperature technology, but also functional materials to achieve high temperature technology. Zhengzhou Sunrise

Refractory Co., Ltd. has been committed to research and develop high quality refractory products for many years, for any further information, contact us, we will do our best to help you.

technological progress of China's glass furnace refractory materials. Compared with the traditional process, modern glass production technology has a qualitative leap which towards the

direction of higher efficiency, lower energy consumption and better product quality. Accordingly, the technical level of glass furnace which is as the core equipment of glass production is also in

constant progress, for instance, widely adopt new technologies to improve the combustion intensity, strengthen heat transfer effect, reduce heat loss and educe the pollution of products and

environment.

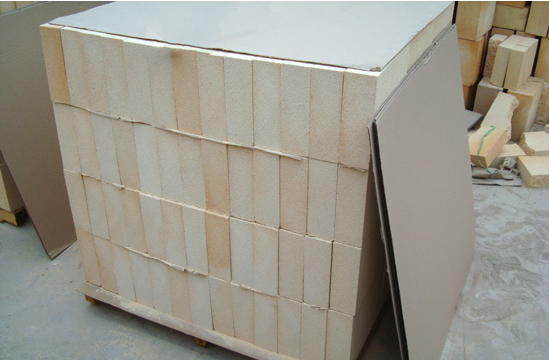

The technological progress of glass furnace requires a variety of high quality refractory bricks as the guarantee condition which can withstand high temperature, resist to strong chemical corrosion

and bear severe stress damage. In order to achieve the new furnace technology of high efficiency, energy saving and low pollution, it is very important to combine and use several kinds of high

quality refractory in one glass furnace, for example, fused cast AZS brick 33# is mainly used in relatively low temperature and corrosive parts of glass furnace such as working ends, feeder

channel.

Go through years of work and the efforts of all aspects, the glass refractory in China has made significant progress, greatly narrowed the gap with foreign, laid a more solid foundation for

enterprise development. As long as the next step to strengthen macro management, concentrating in taro in error problem to solve, we can make greater contributions to the development of glass

industry.

High quality refractory is not only the consumption materials to modern high temperature technology, but also functional materials to achieve high temperature technology. Zhengzhou Sunrise

Refractory Co., Ltd. has been committed to research and develop high quality refractory products for many years, for any further information, contact us, we will do our best to help you.