Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- The Use of Mullite Insulation Bricks

- Manufacturing process of fire clay insula

- Pollution and treatment in the production

- Classification of mullite insulation bric

- Refractory material production process

- the development of the refractory brick i

- Pros and cons of lightweight mullite bric

- Production Process Methods of Refractory

- Aggregates Used For the Production of Ins

- Thermal Shock Resistant Fireproof Heat In

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

How to choose mullite insulation brick

Date:2016-07-14 18:38 | From:Zhengzhou Sunrise Refractory | Author:admin

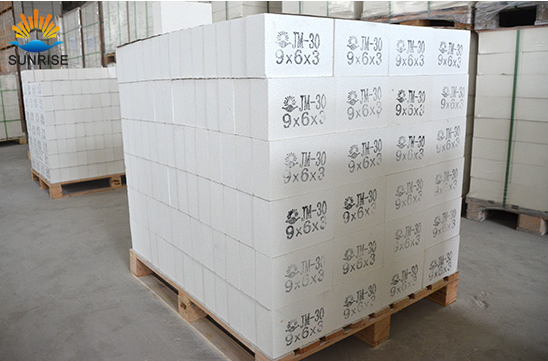

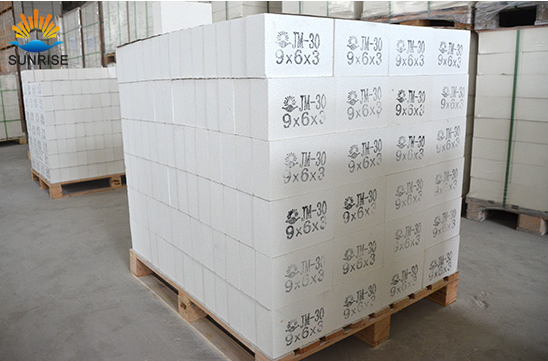

Mullite insulation brick is a common refractory brick, used for roof of hot air stove, blast furnace and furnace bottom, the regenerator of glass furnace, ceramic sintering kiln and so on. It has a lot of

performance, can play a lasting effect on kiln, including its high temperature performance mainly depends on the content of alumina and distribution uniformity of mullite facies and glass, also can

choose to determine how much content of mullite insulating brick according to the performance

Fused mullite brick with high alumina, industry alumina and refractory clay as raw material, adding charcoal or coke fine as a reducing agent, to use reduction melting method after manufacturing

forming. Sintered mullite brick with high bauxite clinker as the main raw material, adding clay or a few raw bauxite as adhesive, molding, sintering and manufacturing.The crystallization of fused

mullite is bigger than sintered mullite, bigger than sintered products of high temperature heat resistant to impact. To choose mullite insulating brick for the kiln and make it play a better effect.

performance, can play a lasting effect on kiln, including its high temperature performance mainly depends on the content of alumina and distribution uniformity of mullite facies and glass, also can

choose to determine how much content of mullite insulating brick according to the performance

Fused mullite brick with high alumina, industry alumina and refractory clay as raw material, adding charcoal or coke fine as a reducing agent, to use reduction melting method after manufacturing

forming. Sintered mullite brick with high bauxite clinker as the main raw material, adding clay or a few raw bauxite as adhesive, molding, sintering and manufacturing.The crystallization of fused

mullite is bigger than sintered mullite, bigger than sintered products of high temperature heat resistant to impact. To choose mullite insulating brick for the kiln and make it play a better effect.