Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- Aggregates Used For the Production of Ins

- Classification of mullite insulation bric

- Manufacturing process of fire clay insula

- Refractory material production process

- The Use of Mullite Insulation Bricks

- Thermal Shock Resistant Fireproof Heat In

- Production Process Methods of Refractory

- Pollution and treatment in the production

- Pros and cons of lightweight mullite bric

- the development of the refractory brick i

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

Selection Of Pore Forming Materials For Lightweight Diatomite Insulation Bricks

Date:2016-05-18 15:25 | From:Zhengzhou Sunrise Refractory | Author:admin

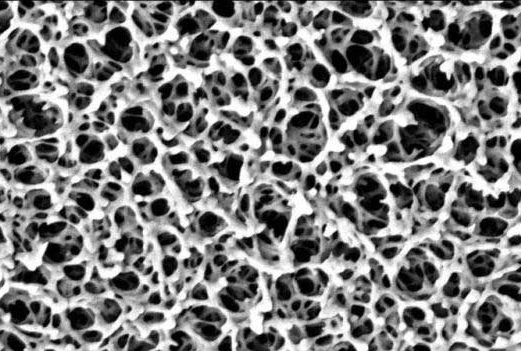

The key for the production of lightweight high strength diatomite insualtion bricks is the selection of pore forming materials. One of the most popular pore forming material is sawdust. However, products made with sawdust are of low quality. Some new materials are gradually used to improve the quality of the insulating bricks.

Polystyrene

Polystyrene has been widely used in the production of lightweight board and coatings. It also has good performance when used as the pore forming material for diatomite bricks, since it has a low content of microbeads (12kg/m3) which is discomposed at 100-700℃ without any ash left. Polystyrene with small particles is ideal. With the increasing of the particle size of polystyrene, both the density and compressive strength increase.

Solid naphthalene

Naphthalene hydrocarbons (C10H8) with a melting point of 80℃ can be transformed into different condensed states such as solid, liquid and gas. Liquid naphthalene is cooled into solid naphthalene. Then it is added into diatomite earth in a proportion of 15-65% after made into thin sheets. During the drying process, it is discharged in the form of liquid of gas. Its process is complex and costly, but diatomite bricks made with it have a low density, high strength and g high thermal load capacity.

Zeolite

Mix diatomite earth, sawdust, zeolite and water in a ratio of 1:0.1:0.1:1.4. First, mix diatomite earth with sawdust uniformly. Then add water and finally zeolite. By casting molding, drying, firing, the mixture is made into the final products. The final products have a density of 450-550kg/m3 and compressive strength of 3.9-4.9 MPa.

Rosin soap

Rosin soap is made by mixing rosin, NaOH and water, heating and then pouring into bone glue solution. Then the rosin soap foam concentrate is diluted with water in a ratio of 1:15 and then formed into high tensile strength spongy foam by stirring. Then pour the mud into the foam bath. Some alum solution is added to stabilize the foam. Stir to get stable foam mud.

Rice husk

Rice husk is a highly siliceous material. It contains 38% cellulose, 22% lignin, 16-20% ash, 18% pentose and 2% other organic matter. After burned, rice husk contains 90-95% SiO2 with a microporous structure. Its mineral phase is cristobalite and its specific surface area is up to 150m2/g. it has good activity and its refractoriness is up to 1650℃. Since SiO2 in the rice husk has volume expansion when generating cristobalite, while clay minerals have volume shrinkage when sintering, the two cancel each other, so the insulation bricks have low shrinkage value. Since SiO2 in the rice husk has high activity and can react with kaolin in the diatomite earth to produce mullite, compressive strength and flexural strength of the bricks will not be reduced.

Spherical close-pore expanded perlite and expanded vermiculite

Spherical close-pore expanded perlite is a new type of insulation material. It can be used to produce diatomite insulation bricks with light weight and high strength. So is spherical close-pore expanded vermiculite.

Gas scum

Urban sewage treatment plants can generate a large number of gas scums with fine particle and high loss on ignition. It has certain plasticity, is easily dispersed in the diatomite, and forms a large number of pores after burning. The final products have low density and high strength.

Cenosphere

Cenosphere is a type of lightweight, hollow aluminosilicate spherical particle sorted from the fly ash discharged from coal-fired boilers in thermal power plants. It has many advantages such as low bulk density, high strength, high refractoriness, good wear resistance, low thermal conductivity, large surface area, good activity and good insulation properties, so it is widely used in the production of insulation materials.

Among those pore forming materials, solid naphthalene and polystyrene have the best performance, but the process is complex and the investment is large. Spherical close-pore expanded perlite also has good performance, but it has regional limit. Cenosphere has general applicability. Zeolite, rosin soap, rice husk, and gas scum is technically feasible, but the key is economic feasibility.