Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- Refractory material production process

- The Use of Mullite Insulation Bricks

- the development of the refractory brick i

- Pollution and treatment in the production

- Aggregates Used For the Production of Ins

- Thermal Shock Resistant Fireproof Heat In

- Production Process Methods of Refractory

- Manufacturing process of fire clay insula

- Classification of mullite insulation bric

- Pros and cons of lightweight mullite bric

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

Sunrise Refractory Analysis of the difference between refractory brick and sintered brick

Date:2019-11-25 15:42 | From:Zhengzhou Sunrise Refractory | Author:admin

Because many consumers are not very clear about refractory bricks and sintered bricks to distinguish between the two, today Sunrise refractory brick manufacturers will tell you clearly what the difference between the refractory brick and sintered brick!

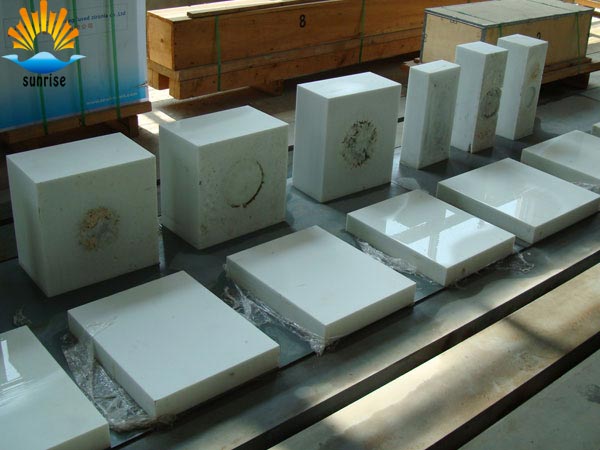

Refractory bricks are referred to as fire bricks. A refractory material fired from refractory clay or other refractory materials. Light yellow or brownish. It is mainly used in smelting furnaces and can withstand high temperatures of 1,580C-1,770C. Also called fire bricks. A refractory material having a certain shape and size. According to the preparation process, it can be divided into fired bricks, unfired bricks, fused bricks (melted cast bricks), and refractory heat-insulating bricks; according to the shape and size, it can be divided into standard bricks, ordinary bricks, and special bricks. It can be used as a high-temperature building material and structural material for building kiln and various thermal equipment, and can withstand various physical and chemical changes and mechanical effects at high temperatures. For example, refractory clay bricks, high alumina bricks, silica bricks, magnesium bricks, and the like.

The difference between the sintered brick and the refractory brick is generally different from the following three points.

1.From the shape color, the ceramics sintered brick is a regular cuboid. Because the raw material is clay, the color is various. The refractory brick is a rectangle with a trapezoidal front. Since the raw material is refractory, the color is basically only light. Yellow or brownish.

2.According to the characteristics of the product, the clay brick has no weathering, no fading, anti-freeze and thaw, abrasion resistance and high compressive strength. On the contrary, the refractory brick has impact resistance, thermal shock resistance and slag resistance. The load softens the temperature and so on.

3.From the application, the ceramics sintered brick is a building material, which will be applied to the exterior walls, pavements, sidewalks, landscape works, etc.; the refractory bricks are used for industrial furnaces, and are used in the construction of various furnaces in the factory. High temperature zone insulation and other functions.

Refractory bricks also belong to sintered bricks, but the temperature at which refractory bricks are sintered is high, and is generally above 1400 degrees.

If you need refractory bricks, please contact Sunrise Refractory and we will provide you with the best quality refractory bricks and the best service.