Product Search

Quickly find the product you need

Products List

Refractory Knowledge

- Pollution and treatment in the production

- The Use of Mullite Insulation Bricks

- Manufacturing process of fire clay insula

- Pros and cons of lightweight mullite bric

- Refractory material production process

- Production Process Methods of Refractory

- the development of the refractory brick i

- Thermal Shock Resistant Fireproof Heat In

- Classification of mullite insulation bric

- Aggregates Used For the Production of Ins

Products List

- Phone:0086-370-63838939

- Email:sales@sunriserefr.com

- Office Address: No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

What is Diatomite Insulation Brick?

Date:2015-11-30 22:27 | From:Zhengzhou Sunrise Refractory | Author:admin

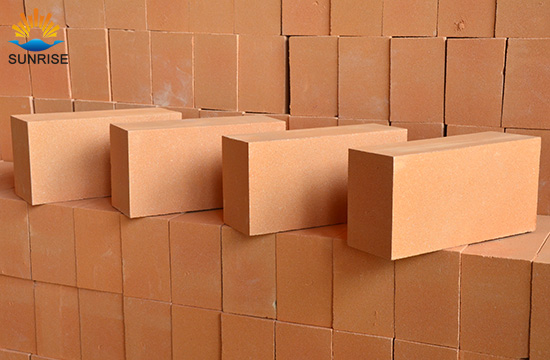

Diatomite Insulation Brick is an insulation material made of high diatomite, bonding with other porous materials. With advantages of non-deformation, non-toxic and easy-to-install, it is an ideal insulation material.

Diatomite Insulation Brick has a large number of micro-pores. Compared to fire clay insulation brick, high alumina insulation brick and ceramic fiber products, it has advantages of light weight, high strength, low bulk density, low thermal conductivity, good insulation and energy-saving effect and low price.

Diatomite Insulation Brick is made of natural porous diatomite, combined with a small amount of clay and combustible materials, by kneading, shaping, drying and firing.

Diatomite Insulation Brick has high porosity and loose structure, so it has good insulation performance, but it cannot be used in the areas in direct contact with molten slags and metals. It has low mechanical strength, especially after damped, so it cannot be used in load-bearing structures. It has poor wear resistance and cannot be used in badly worn areas in contact with charges.

Its refractoriness is only 1280℃, so its maximum operating temperature is 900~1000℃. It can only be used in the mid-temperature insulation layer.

It can not only increase the temperature, shorten the heating time and reduce the fuel consumption, but also has a good sound absorption effect. It is the preferred choice for the energy saving equipment. It is widely used in the electricity, metallurgy, petroleum, chemical, cement, ceramics, textiles, glass and light industry.